Cooling Tower Systems

Traditional Cooling Tower Operations

Cooling towers are primarily used to cool water in air conditioning systems. They are also used in process industries to cool materials. The warm water returning from the chillers is pumped to the top of the tower and distributed by spray nozzles over a medium known as “fill”. The purpose of the fill is to expose as much of the water’s surface as possible. As the water drops through the fill, fresh air from outside the cooling tower is forced through the tower. The water, cooled by partial evaporation, then falls into a basin at the bottom and is circulated back to the chiller to start the process all over again.

Cooling tower water quality tends to be extremely poor. Cooling tower traditional treatment is based on EXTREME chemical use only. Quioz and its partners sees an interesting and positive opportunity to create an entirely new technology & activity base in bringing chemical free products to market while supporting environmental integrity and responsibility.

There are three main problems surrounding cooling towers:

1. Water quality control is difficult due to the following reasons;

- Evaporation rate

- Environmental contaminants

- Extreme chemical use

2. Chemical dependence is promoted by an industry that serves and maintains cooling towers. Most cooling tower manufacturers do nothing about recommending or selling treatment equipment along with the towers. In most cases, it is left up to the end users to set up the treatment method. The cost of chemicals is lower on the front end than water treatment equipment, but far higher based upon the ongoing nature of the use

3. The water waste issue. For example, it is not uncommon to see a 3,000-gallon cooling

tower constantly draining water, then constantly replenishing raw water just to lower TDS.

This ever-increasing TDS is contributed to a great degree by the chemicals that are used for treatment.

Not only is there an extreme amount of water being wasted on a daily basis, but the

environmental impact from the chemical-laden wastewater is deplorable. This chemical-laden wastewater eventually will make its way into our lakes, streams, rivers and groundwater. That is why this wastewater is becoming the subject of more stringent governmental regulations worldwide.

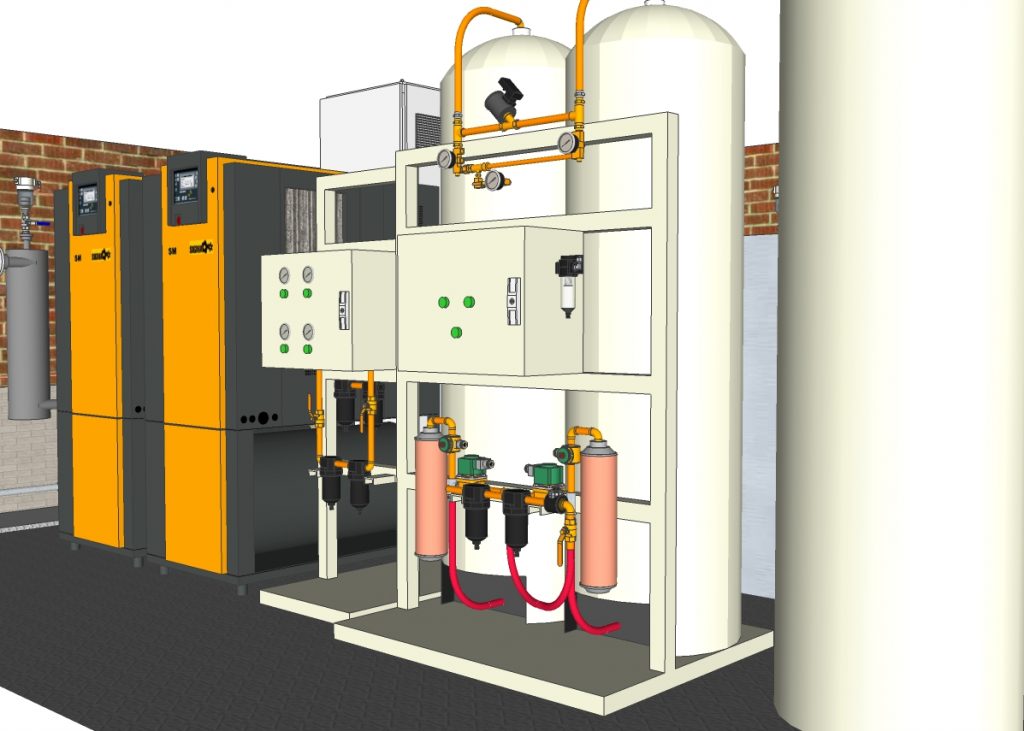

Chemical-Free Cooling Tower with Quioz Environmental Ozone Technology

Ozone is primarily used in cooling tower treatment for the following reasons;

- Bacteria/virus elimination/prevention

- Organic build-up elimination/prevention

- Blow-down reduction/elimination

- Bleed-off reduction/elimination

- Improved clarity

- Scale reduction

- Cooler running temperatures where scale is inhibited or reduced

- Reduction or elimination chemicals needed for algae control

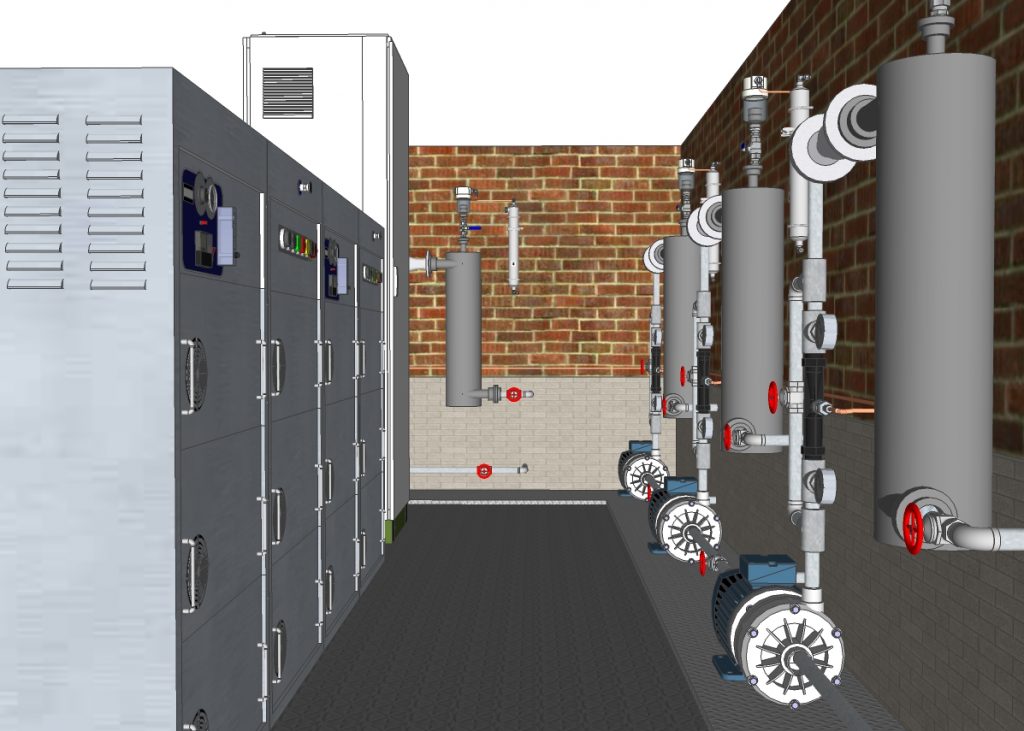

Ozone is injected into the water flow created by a separate circulation pump. This pump pulls the water from the tower’s sump or basin and sends it to the ozone injector, contact tank and scale removal/filtration system. Lastly, the treated water returns back to the sump or basin. The principle is to treat the water and eliminate/reduce the following contaminants.

- Scale-forming minerals

- Organics

- Algae

- Harmful microbes

The clean water then is used to clean the entire sump, basin, pipes and peripheral equipment. The ozone treatment system is simple and can be broken down into three easy steps:

- Ozone injection. Ozone is injected into the side stream flow. Oxidation starts to take place immediately on microbes, organics, bacteria and viruses.

- Contact/mixing. A contact tank helps to further the ozone’s ability to oxidize particles allowing them time to react prior to returning to the system. As water flows down the off-gas tank, ozonated water rises and strips any gas in the incoming water.

- Filtration, scale control, particle removal. Possibly the most important aspect of any water treatment is the removal of the particles that have been oxidized. Without this step, all you have done with the ozone is change the structure of the particles by making them larger, insoluble and/or heavier. This step is necessary for systems that require scale control and particulate removal.

It is very important not to construct an ozone unit too large to handle the bacteria, scale and algae. The problem encountered at this point could be corrosion. If you carry an ozone residual too high to de-scale downline you stand a chance of creating a corrosive situation in the sump and its adjacent equipment. For this reason, it’s important to utilize existing water treatment technology and equipment in conjunction with ozonation. The result is a system that works without high maintenance, dangerous chemicals, extreme water waste and costly corrosion.

Please contact us via email at: sales@quioz.com. For info in Spanish, kindly visit our website covering Latin America: www.quioz.cl

Web-Design By QUIOZ MKT | © 2021 Quioz Scandinavia AS